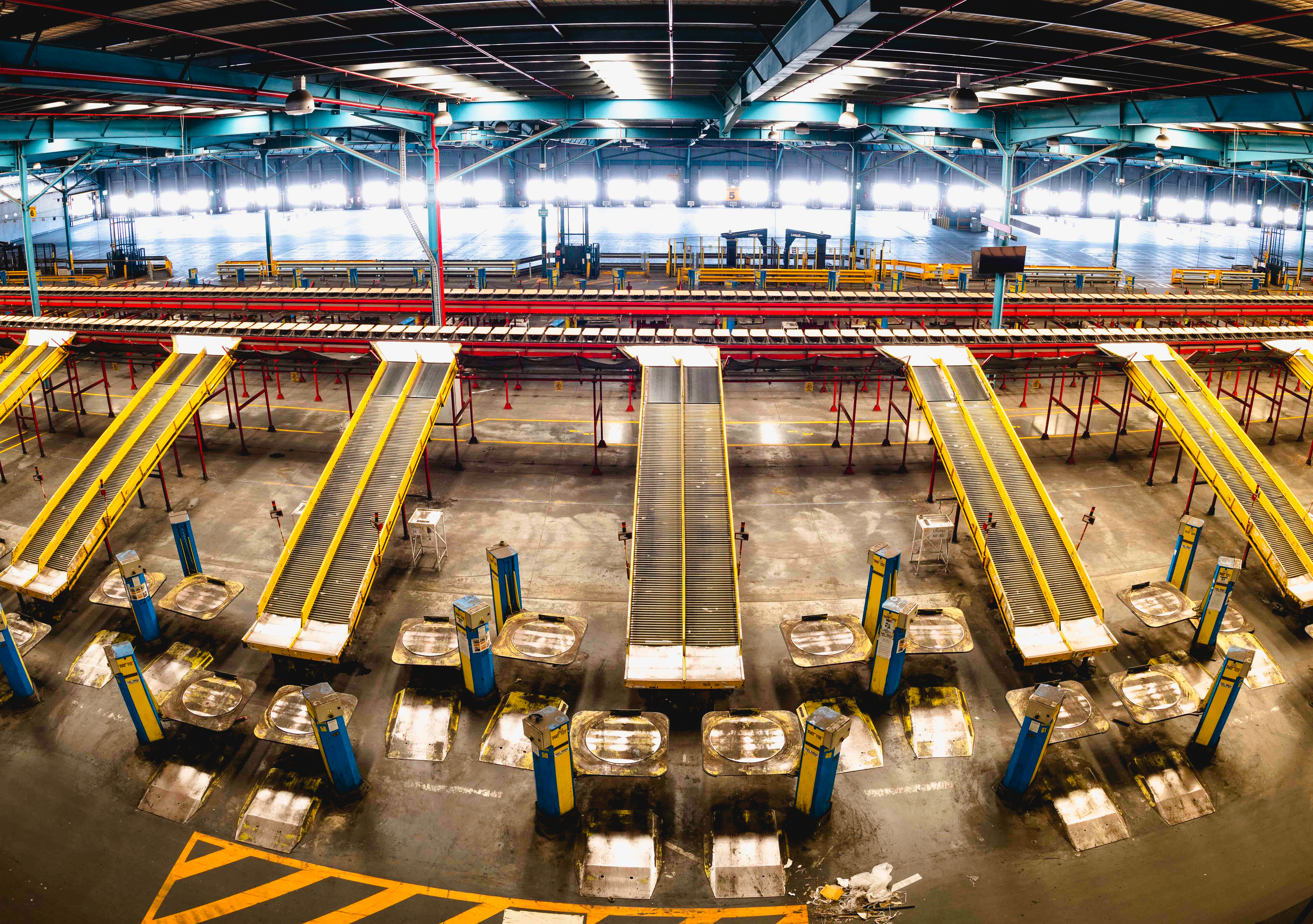

A former distribution centre located in a popular Melbourne logistics hub, this project footprint was over 250,000m² and, at its highest point, stood at a colossal 30 meters. MANN deployed over 17 excavators simultaneously working with various hydraulic attachments, removing up to 150 loads per day. A state-of-the-art number plate tracking system, combined with a weighbridge, ensured a seamless truck flow, while a back-to-base system provided real time updates on tracking. Due to the sheer height of the fully automated shed, a carefully designed and calculated structural pre-weakening method was applied to perform a successful, engineer-induced collapse. Concrete slabs and footings were removed and processed onsite. Hydraulic attachments were used to crush concrete to detach majority of the steel to be recycled. Existing underground service tunnels were trenched and battered for removal. Upon completion, the grounds were graded and levelled in preparation for the civil teams to commence work. All demolition material was organised onsite and recycled to deliver a successful project on time and a 97% recycle rate. Woolworths Distribution Centre

Challenges & Solutions

Outcome